At Albert Hoffmann GmbH our customers’ designers find contacts who will jointly find solutions for their complex requirements. In this context, we can offer our know-how of more than 100 years. Something quite unparalleled is that we perform all necessary tasks in-house: from model making through heat treatment to finial processing and materials testing.

Concrete with highly abrasive characteristics makes high demands on steel castings in stationary and mobile concrete pumps. Moreover, the required geometries, in particular the wall strengths and their runs, combined with the material to be selected properly pose a challenge. Our customers appreciate our balanced material quality, dimensional tolerance and dynamic warehousing.

To be able to serve customers from the energy sector you must not only show a high degree of competence in casting and material, but also skills when it comes to generating the highest possible benefit for the customer. Understanding the products and the customers’ processes is elementary. And all this with our continuing reliability: it is not only once or twice we deliver to meet the high demands!

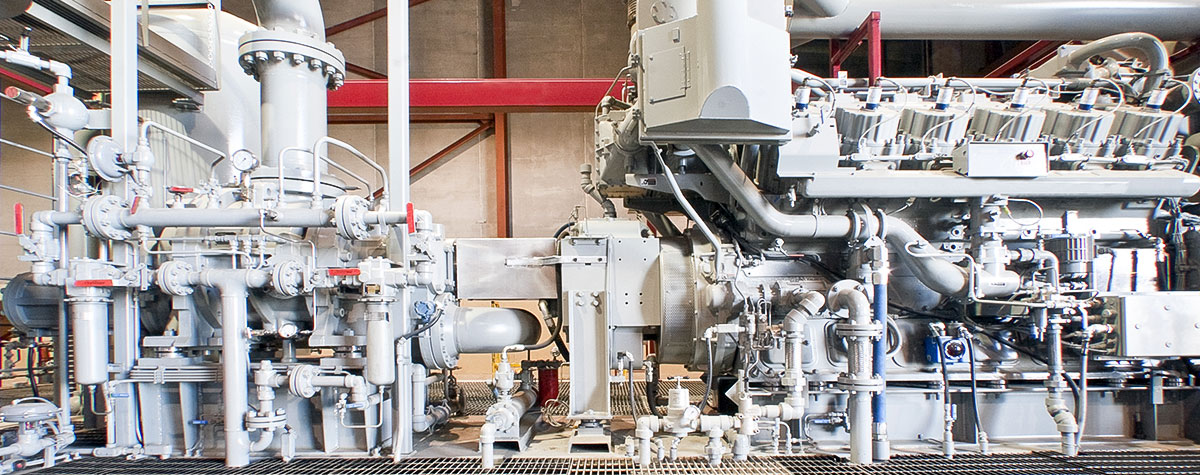

Steel casting components for compressors must comply with high demands. Again here, we can show our strengths as regards material competence and reliability to minimize the risks at your premises or for you. This is based on our long-term experience with the most renowned OEMs.

For demanding power plant components with their high requirements, we guarantee quality that bears up to the influencing pressures. Clearly defined quality classes and highest interior qualities are the prerequisite for the problem-free use of our steel casting parts in power plant construction.

High static and dynamic loads of the mining devices impose high demands on steel casting parts in upper carriages and undercarriages. In this context low temperatures of -40°C are not seldom. Our customers appreciate our comprehensive design and material consultancy. Moreover, with our own heat treatment shop we offer a higher degree of material knowledge and process reliability. Working together, the goal of a high availability of equipment will be achieved.

The willingness as to versatility (from the pattern to the finished part), flexibility (to adapt to the dynamic developments of customer demand) and permanent reliability are important components for our customers. With our material expertise, in particular based on our melting technology and specially developed hardening and tempering procedures, we achieve material values that can be compared with procedures of secondary metallurgy. To satisfy ever changing customer demands we offer our customers targeted warehousing that is regularly controlled according to their needs.

Depending on the medium and pressure for the most diverse clientele, different material properties are required. With our material program of more than 80 different materials we can offer our customers the desired flexibility. Small melting units and the possibility of individual manufacture or the smallest series in our hand molding shop round off the requirements of our customers.

We can solve problems with you as equals. Since the beginnings in 1970, Albert Hoffmann GmbH has been dealing with shredder systems & rotors and now we can offer a comprehensive portfolio for the recycling industry, from single units to turn-key processing plants. Our decade-long experience combined with our worldwide customer contacts is the basis for our sustainable success in the field of wear-resistant casting. Our customers don’t want to do without our numerous in-house material developments and further developments and our all-round consulting.

For more than five decades we have been delivering pump spare parts suitable for suction dredges of all renowned pump manufacturers (Warman, Habermann, Idreco, Metso, Marheine). To this end we deliver to customers all over Europe. Our success is based on the material properties of our VC steel casting material program for high abrasive stresses. Our program comprises cases, impellers or gyros, wear discs, shot cages or suction nozzle cages and impeller caps. We have all models for the series KBPL 250, KBPL 300, KBPL 400, PK 300, PK 350, Warman 8/6; Warman 10/8; Warman12 / 10 and Warman 14/12. Also for suction excavators with Metso pumps, Marheine, Bagema, Fortmeier and Zimmermann & Jansen. Besides our VC materials, our customers rely on the constant size accuracy and our targeted warehousing. Moreover, we have been cooperating for many years with experienced experts since we want to offer our customers comprehensive consulting and additional service. Talk to us about your “exotic”. We would be happy to take a look at your pump on site and with the help of our modern scanner technology we can offer you inexpensive replicas with improved material properties.

Albert Hoffmann GmbH has all the necessary approvals for the manufacture of parts for the Federal Railway. In the context of quality assurance we offer the following testing technologies: Ultrasonic test according to DIN EN 12680 and DIN 1690, magnetic particle testing according to DIN EN 1369, dye penetrant inspection according to DIN EN 1371 to X-ray inspection according to DIN EN ISO 9712. We supply our customers with the highest quality for commuter trains, high-speed trains and freight trains.

Whether it is a new construction or overhaul, speed is always important for our customers. We offer our customers the possibility of being on site directly during the development phase or when the requirements are gathered when the vessel enters the port. With our latest technologies we will assist in substantiating the demand and designing it in a way that can be realized. We are happy to ease your workload.

In addition to the variety of different hammers we have been offering for more than four decades with our reliable, specially heat-treated chrome-nickel quality and austenitic manganese steel, all wear & tear parts installed in a shredder are manufactured in-house.

We supply the most renowned companies of this industry with spare parts for crushers, for different mills and cement mills. Our NCM and VNG range of materials, specifically developed for this application, offers our customers a considerably higher and guaranteed service life of our castings and thus longer availabilities of their own systems.

In this business unit we sum up a variety of the sections of engineering. It is characterized by a high number of customers, but also by project-related requirements and short delivery times. If our warehousing is not able to offer support due to sporadic demands, that is where our speed comes in. Here, quality and delivery reliability is the prerequisite for customer satisfaction.