Please find below an overview of our rotor types. They prove their worth every day under severe working conditions.

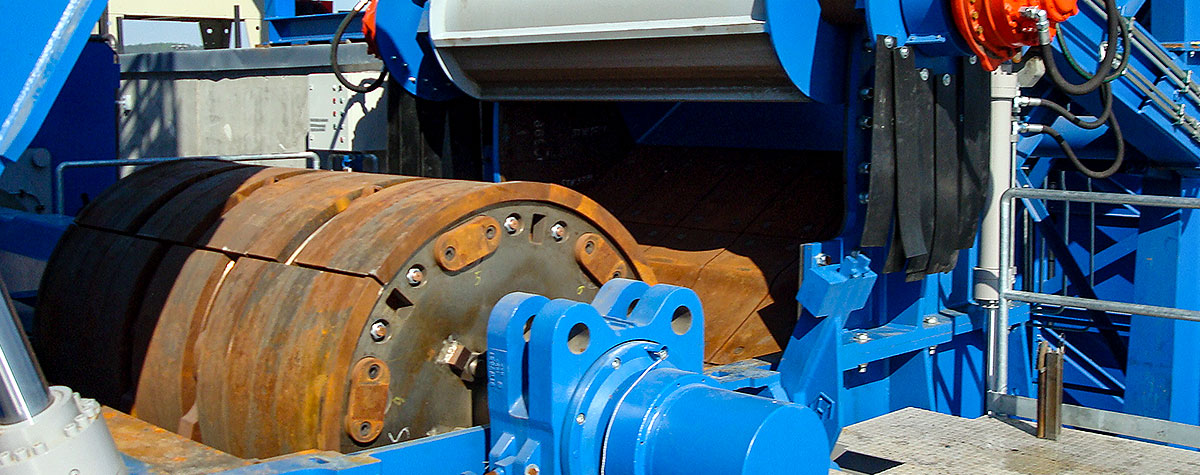

This is the most common type of rotor run with rotor protective caps as wear protection. It is characterized by long service life and comfortable shredding behavior. We offer it as a 6- or 4-axis rotor.

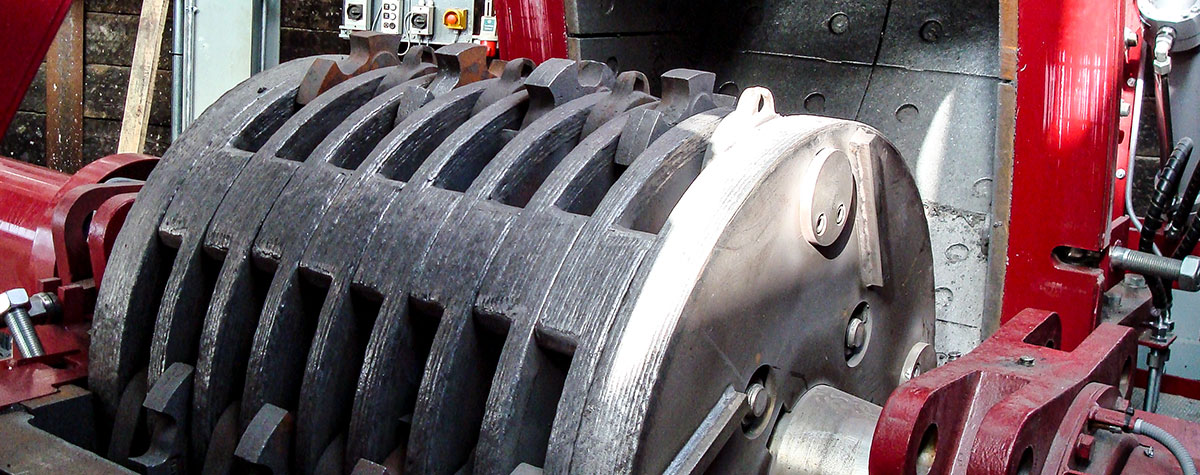

This is a type of rotor run hard-faced in the working area for wear protection. It is characterized by a high output per hour since it is run with a smaller diameter compared to the cap rotor. We offer this type of rotor as a 6- or 4-axis rotor.

This rotor developed in-house for specific use is composed of cast 3-axis arms that are mounted offset. Thereby the 6-axis arm rotor is produced that can be used in every shredder as an option to the disk rotor. Due to this molding the rotor works actively in the shredding process and with considerably easier replacement of rotor caps at the same time.

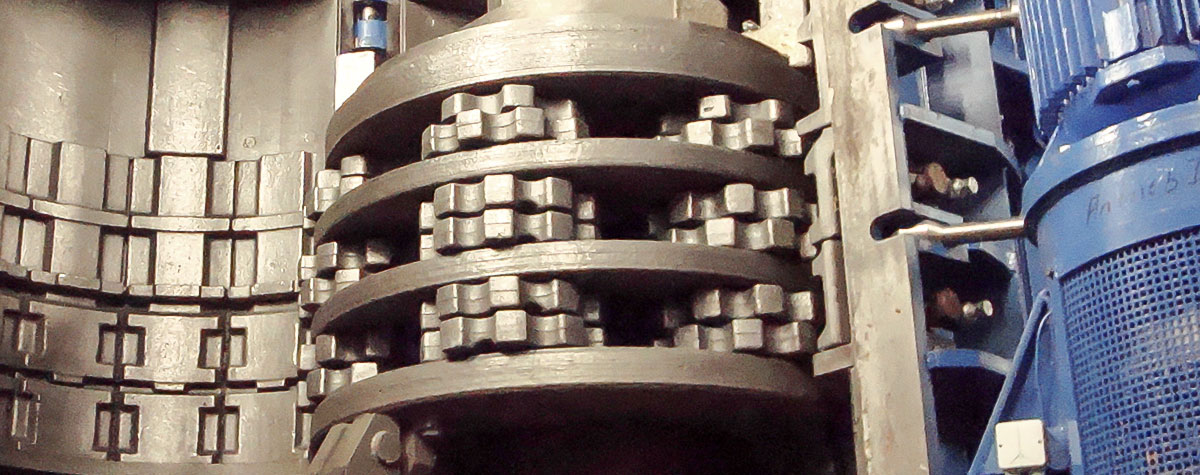

This rotor is usually used in American shredder systems. It is normally operated with 750 revolutions per minute and protected with coifs at the middle disks. The end disks are either protected by protective caps or hard-facing is applied.

The vertical rotor is the heart of a vertically running mill that, known in the market as the artist of ball-typed closing, for producing cooling scrap among others. By means of selectable chicaneries between impact rings / hammers and the wall lining the material to be shredded is conveyed to the discharge via its dead load. Just recently the vertical mill with its vertical rotor has become very popular with our customers as a high-performance partner for numerous materials.

For special applications we offer our cast rotors with offset hammer positions. Our team will be pleased to advise you on the type of rotor suitable for you.